| Foodoric and associated companies are chemicals manufacturing companies exporting and supplying Sodium Lactate USP BP FCC Food Grade, operated in India USA UAE Asia Europe and other countries around the world. The associates have one or more of certifications like c-GMP, ISO-9001, ISO-14001, ISO-22000:2005, FSSC 22000; OHSAS 18001; Kosher and Halal Certified; HACCP, FSSAI and FDA - GMP approval. Buyers are assured of good quality and CIF wholesale and retail price for supplies of our Acetic Acid. |

Sodium Lactate USP BP FCC Food Grade Manufacturers Suppliers

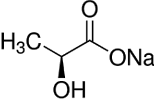

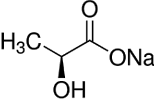

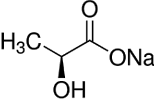

Sodium Lactate

USP BP FCC Food Grade

Sodium Lactate: CAS Number: 72-17-3, Molecular Formula: C3H5NaO3, Molecular Weight: 112.06

Sodium Lactate Solution FCC Food Grade

2-Hydroxypropanoic Acid, Monosodium Salt

C3H5NaO3 Formula wt, anhydrous 112.06

CAS: [72-17-3]

DESCRIPTION

Sodium Lactate Solution occurs as a clear, colorless or practically colorless, slightly viscous liquid that is odorless or has a slight, not unpleasant odor. It is miscible with water. It is normally available in solutions with concentrations ranging from 60% to about 80%, by weight.

REQUIREMENTS

Indicate the content, by weight, of sodium lactate (C3H5NaO3).

Identification: A sample gives positive tests for Sodium and for Lactate.

Assay: Not less than 50.0%, by weight, and not less than 98.0% and not more than 102.0%, by weight, of the labeled amount of C3H5NaO3.

Chloride: Not more than 0.05%.

Citrate, Oxalate, Phosphate, or Tartrate: Passes test.

Cyanide: Not more than 0.5 mg/kg.

Lead: Not more than 2 mg/kg.

Methanol and Methyl Esters: Not more than 0.025%.

pH: Between 5.0 and 9.0.

Sugars: Passes test.

Sulfate: Not more than 0.005%.

Sodium Lactate Solution USP

Sodium Lactate Solution is an aqueous solution containing not less than 50.0 percent, by weight, of monosodium lactate. It contains not less than 98.0 percent and not more than 102.0 percent of the labeled amount of C3H5NaO3.

Label it to indicate its content of sodium lactate.

Identification: It responds to the tests for Sodium and for Lactate.

pH: between 5.0 and 9.0.

Chloride: A portion, equivalent to 1 g of sodium lactate, shows no more chloride than corresponds to 0.7 mL of 0.020 N hydrochloric acid (0.05%).

Sulfate: To 10 mL of a solution (1 in 100) add 2 drops of hydrochloric acid and 1 mL of barium chloride TS: no turbidity is produced.

Heavy metals: Dilute a quantity of Solution, equivalent to 2.0 g of sodium lactate, with 1 N acetic acid to 25 mL: the limit is 0.001%.

Sugars: To 10 mL of hot alkaline cupric tartrate TS add 5 drops of Solution: no red precipitate is formed.

Limit of citrate, oxalate, phosphate, or tartrate: Dilute 5 mL with recently boiled and cooled water to 50 mL. To 4 mL of this solution add 6 N ammonium hydroxide or 3 N hydrochloric acid, if necessary, to bring the pH to between 7.3 and 7.7. Add 1 mL of calcium chloride TS, and heat in a boiling water bath for 5 minutes: the solution remains clear.

Limit of methanol and methyl esters:

Potassium permanganate and phosphoric acid solution: Dissolve 3 g of potassium permanganate in a mixture of 15 mL of phosphoric acid and 70 mL of water. Dilute with water to 100 mL.

Oxalic acid and sulfuric acid solution: Cautiously add 50 mL of sulfuric acid to 50 mL of water, mix, cool, add 5 g of oxalic acid, and mix to dissolve.

Standard preparation: Prepare a solution containing 10.0 mg of methanol in 100 mL of dilute alcohol (1 in 10).

Test preparation: Place 40.0 g in a glass-stoppered, round-bottom flask, add 10 mL of water, and add cautiously 30 mL of 5 N potassium hydroxide. Connect a condenser to the flask, and steam-distill, collecting the distillate in a suitable 100-mL graduated vessel containing 10 mL of alcohol. Continue the distillation until the volume in the receiver reaches approximately 95 mL, and dilute the distillate with water to 100.0 mL.

Procedure: Transfer 10.0 mL each of the Standard preparation and the Test preparation to 25-mL volumetric flasks, to each add 5.0 mL of Potassium permanganate and phosphoric acid solution, and mix. After 15 minutes, to each add 2.0 mL of Oxalic acid and sulfuric acid solution, stir with a glass rod until the solution is colorless, add 5.0 mL of fuchsin-sulfurous acid TS, and dilute with water to volume. After 2 hours, concomitantly determine the absorbances of both solutions in 1-cm cells at the wavelength of maximum absorbance at about 575 nm, with a suitable spectrophotometer, using water as the blank: the absorbance of the solution from the Test preparation is not greater than that from the Standard preparation (0.025%).

Sodium Lactate BP Grade Ph Eur

DEFINITION

Solution of a mixture of the enantiomers of sodium 2-hydroxypropanoate in approximately equal proportions.

Content

Minimum 50.0 per cent m/m of sodium 2-hydroxypropanoate (C3H5NaO3); 96.0 per cent to 104.0 per cent of the content of sodium lactate stated on the label.

CHARACTERS

Appearance: Clear, colourless, slightly syrupy liquid.

Solubility: Miscible with water and with alcohol.

IDENTIFICATION

A. To 0.1 ml add 10 ml of water. 5 ml of the solution gives the reaction of lactates.

B. It gives reaction of sodium.

TESTS

Solution S: Dilute a quantity of the substance to be examined corresponding to 40.0 g of sodium lactate to 200 ml with distilled water.

Appearance of solution: The substance to be examined is clear and not more intensely coloured than reference solution.

pH: 6.5 to 9.0 for the substance to be examined.

Reducing sugars and sucrose: To 5 ml of the substance to be examined add 2 ml of dilute sodium hydroxide solution and 0.2 ml of copper sulphate solution. The solution is clear and blue and remains so on boiling. Add to the hot solution 4 ml of hydrochloric acid. Boil for 1 min. Add 6 ml of strong sodium hydroxide solution and heat to boiling again. The solution is clear and blue.

Methanol: the limit is 50 ppm calculated with reference to sodium lactate, if intended for use in the manufacture of parenteral dosage forms, dialysis, haemodialysis or haemofiltration solutions.

Chlorides: Maximum 50 ppm calculated with reference to sodium lactate.

Oxalates and phosphates: To pass the test.

Sulphates: Maximum 100 ppm calculated with reference to sodium lactate.

Aluminium: Maximum 0.1 ppm, if intended for use in the manufacture of parenteral dosage forms, dialysis, haemodialysis or haemofiltration solutions.

Atomic absorption spectrometry: To pass the test.

Barium: To 10 ml of solution S add 10 ml of calcium sulphate solution. Allow to stand for 30 min. Any opalescence in the solution is not more intense than that of a standard prepared at the same time and in the same manner using a mixture of 10 ml of solution S and 10 ml of distilled water R.

Iron: Maximum 10 ppm calculated with reference to sodium lactate.

Heavy metals: Maximum 10 ppm calculated with reference to sodium lactate.

Bacterial endotoxins: Less than 5 IU/g, if intended for use in the manufacture of parenteral dosage forms without a further appropriate procedure for the removal of bacterial endotoxins.

Sodium Lactate Manufacturers Suppliers:

Foodoric Group of Cos

India, USA, UAE, Europe

e-mail: info@foodoric.com

Copyright Last 14 June, 2025

Sodium Lactate Suppliers, Exporters, Importers, Manufacturers offering good CIF wholesale and retail prices, quality and online information.

A jackal woke up early in the morning and went in to the plains. He looked at his long shadow in the rising morning sun and said to himself, "I must have a camel for my meal today".

He kept moving around till noon and it was getting hot and the jackal was tired. He was also hungry and thirsty. He looked at his small shadow in the mid-day sun. He murmered, "I was only joking about the camel, a mouse will do".